Clean Room Wall System

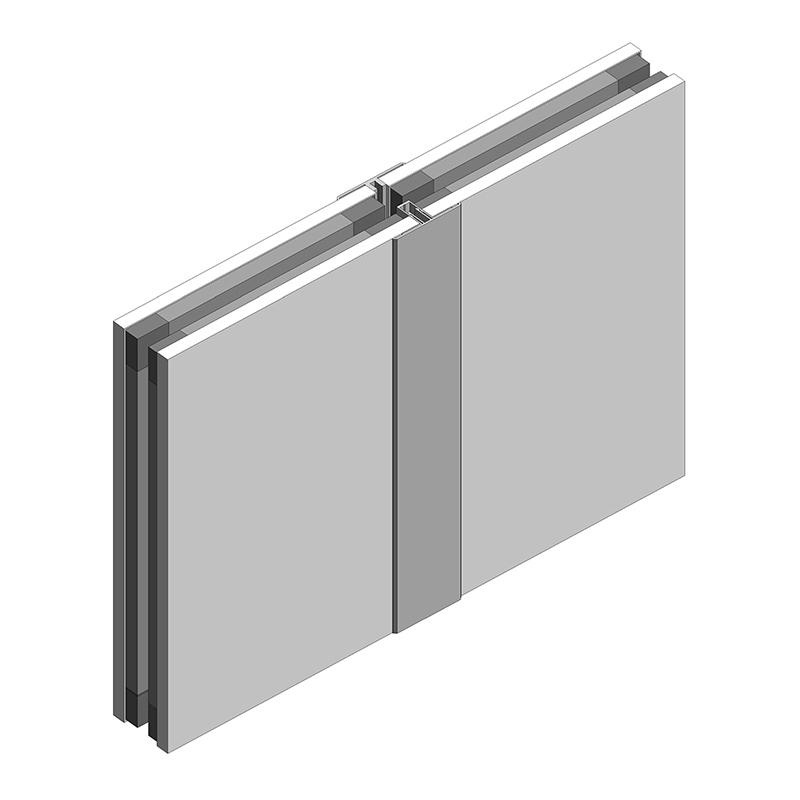

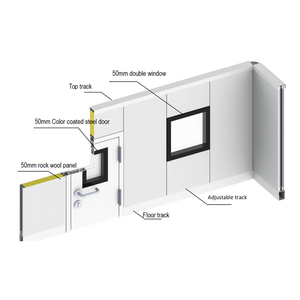

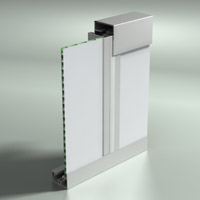

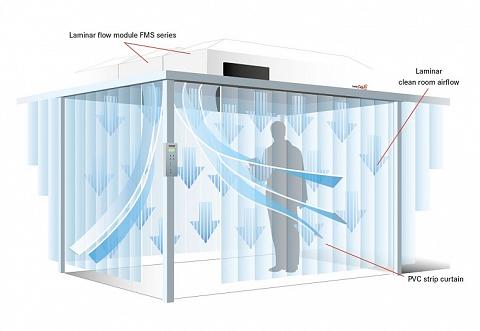

Clean room wall system. Our pharma-wall cleanroom system is a new design by Octanorm which consists of an aluminium extrusion core metal panels with a pharmaceutical grade anti-bacterial coating and window glazing. Standard specifications are given below but note that ICLEAN wall panels can also be customized per requirement. In clean rooms are installed at the point of air discharge into the room.

Cleanroom Wall Panels System. Modular cleanroom walls are used in modular cleanrooms to provide hospitals laboratories and manufacturing facilities a sterile environment that is flexible and affordable. These wall systems are easier to install with less mess than conventionally built walls while providing comparable performance.

Our high specification UltraTech Precision wall and ceiling panels have been specially designed for use in the most stringently regulated cleanroom environments. Unlike traditional stick-built approaches the Plascore cleanroom wall system arrives at the job site cut to height with all the components clean packaged and ready for fast installation. Typical applications include laboratories pharmaceutical cleanrooms and environments subject to FDA regulations.

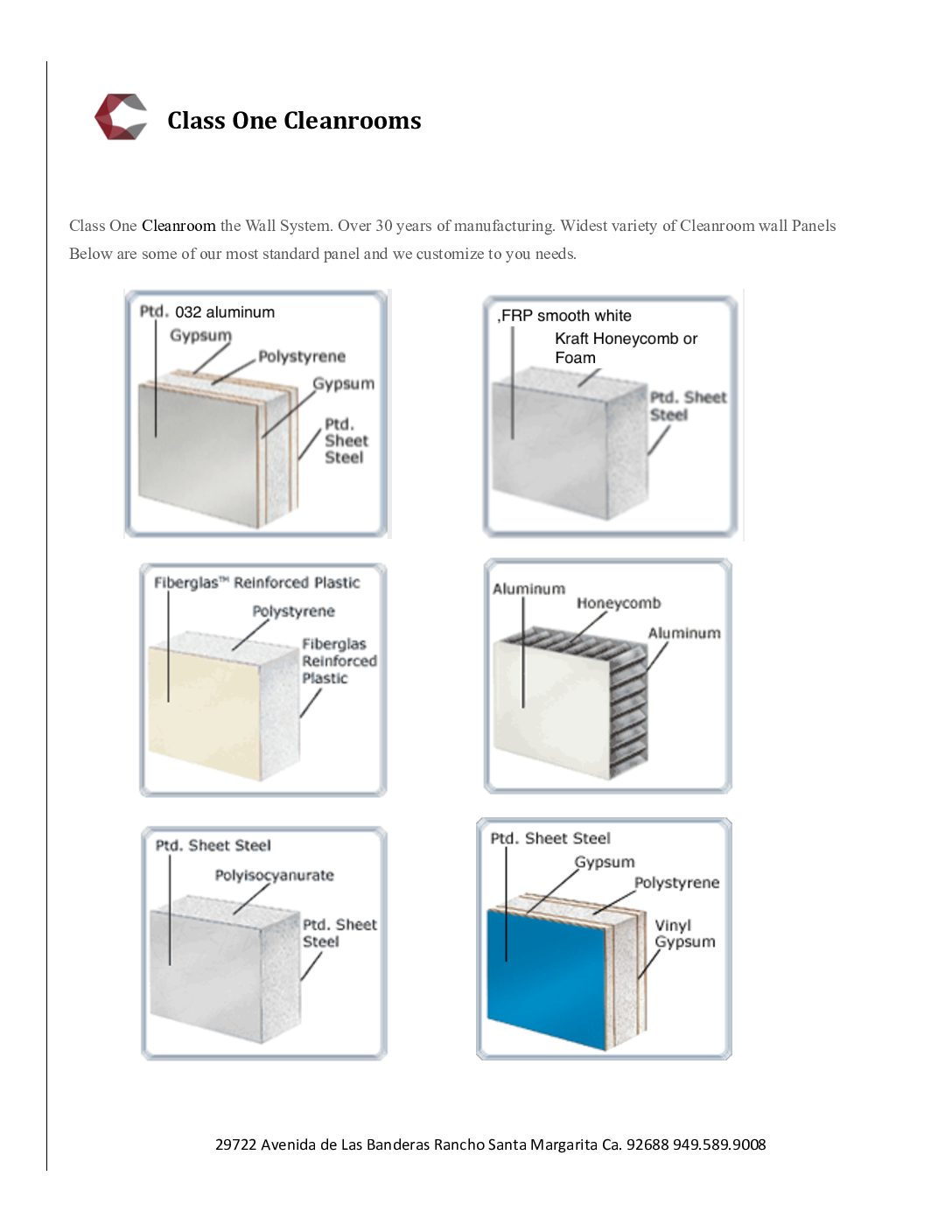

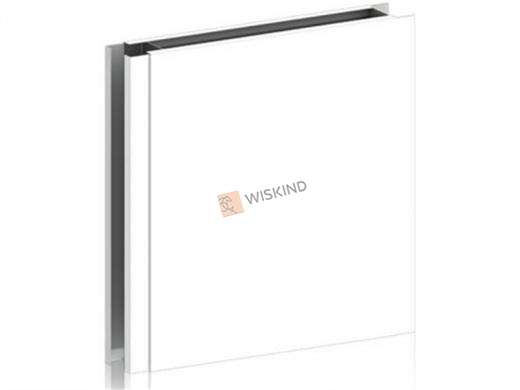

As a general rule of thumb the cleaner the cleanroom needs the more air it will need to use. Our modular clean room panels are designed to meet the needs of state-of-the-art technology. 3 thick modular cleanroom wall system panels are high pressure laminate covered hardboard factory laminated to both sides of honeycomb or foam core.

All clean room panels are manufactured bespoke to the project and are available with number of skins and finishes including PET Foodsafe Laminate Polyester uPVC Stainless Steel and many more. Plascore cleanroom wall systems modular design gives you greater return on your investment by reducing onsite construction cost and installation time. These totally customisable solutions have many uses such as complete clean rooms mini-environments and room-in-room units.

There are four different framing studs available for this system to allow for single or double sided walls retrofit to existing. Specializes in manufacturing and designing of modular clean room panels for electronic pharmaceutical food and biotechnological industry. GI Pre-Coated GI powder-coated SS -304.

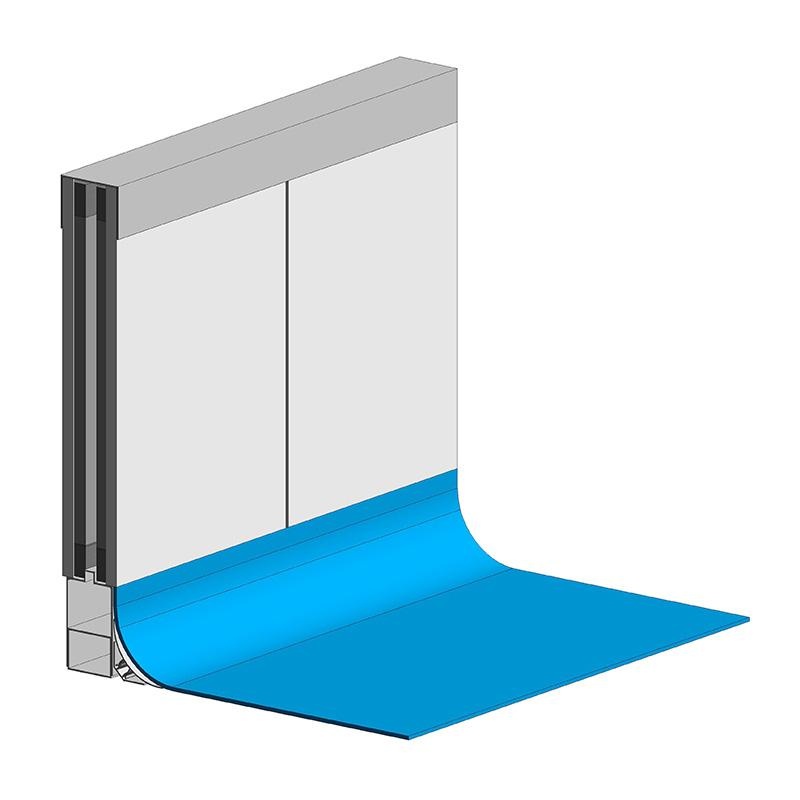

The one piece corner system completely eliminates the various corner joints between the wall panels which ensures the smoothness of the wall panels and avoids the impact of joint cracking and. This allow electrical outlets and mechanical components to be placed within the cleanroom panels cavity prior to the on-site installation.

With our stick-built construction that provides tight gasketed joints and wide range of panel types the Neslo Wall System can accommodate any industry.

Our modular clean room panels are designed to meet the needs of state-of-the-art technology. These wall systems are easier to install with less mess than conventionally built walls while providing comparable performance. Fiberglass Reinforced Plastic FRP. Our CleanWall system is a non-progressive demountable cleanroom wall that uses a batten system to attach the wall panels to the studs. QuadCore MF Aluminium Honeycomb. As a general rule of thumb the cleaner the cleanroom needs the more air it will need to use. Use for a seamless Glasbord installation that is easy to clean. This means that the cleanrooms Air Handling Units AHU typically consumes over 60 of all the site power in most facilities. Our pharma-wall cleanroom system is a new design by Octanorm which consists of an aluminium extrusion core metal panels with a pharmaceutical grade anti-bacterial coating and window glazing.

These totally customisable solutions have many uses such as complete clean rooms mini-environments and room-in-room units. This allow electrical outlets and mechanical components to be placed within the cleanroom panels cavity prior to the on-site installation. Unlike traditional stick-built approaches the Plascore cleanroom wall system arrives at the job site cut to height with all the components clean packaged and ready for fast installation. All clean room panels are manufactured bespoke to the project and are available with number of skins and finishes including PET Foodsafe Laminate Polyester uPVC Stainless Steel and many more. Use for a seamless Glasbord installation that is easy to clean. FRP cleanroom wall system. This means that the cleanrooms Air Handling Units AHU typically consumes over 60 of all the site power in most facilities.

Post a Comment for "Clean Room Wall System"